Nanjing Chuangbo Extrusion Equipment Co., Ltd. represented by its main product -- parallel co-rotating twin screw extruder, is committed to manufacturing, machining essential components and completing equipment

in whole line applied for high polymer compounding and modication (including reactive extrusion and post -processing), and researching as well as developing applications in the sectors of related proces- sing technologies and engineering until turn-key project.

CHUANGBO WORKSHOP

CHUANGBO EXHIBITION

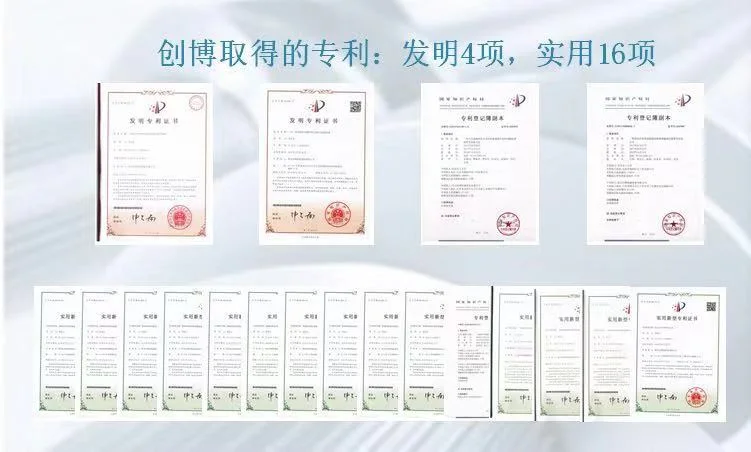

CHUANGBO PATENT

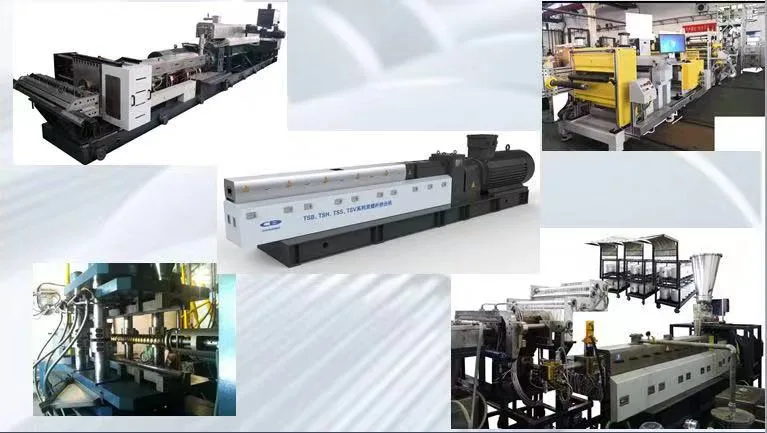

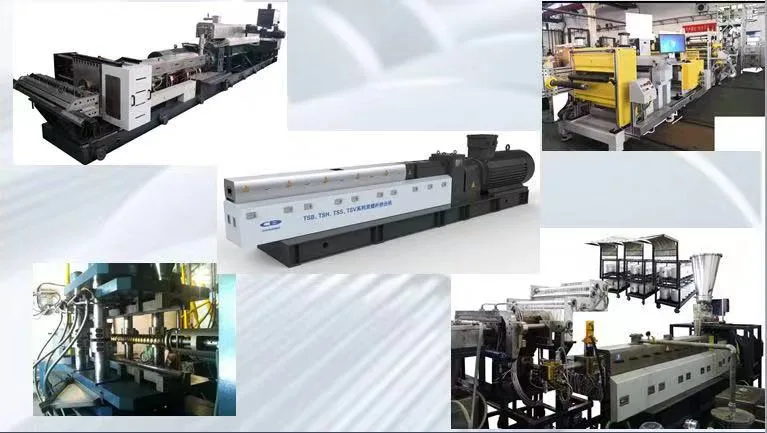

CHUANGBO MACHINE

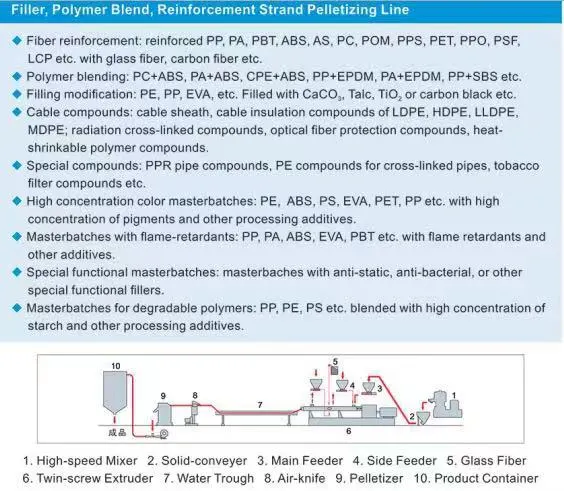

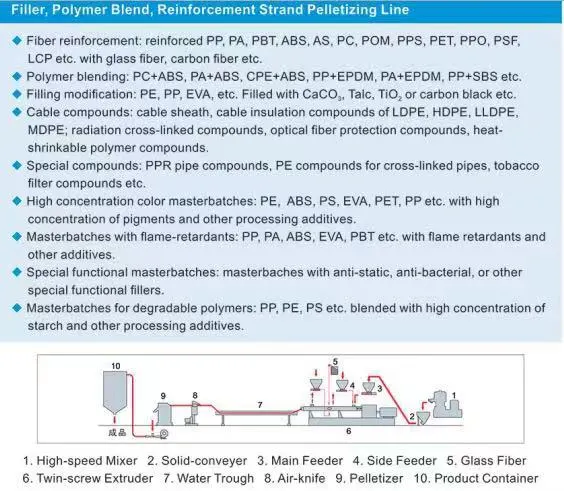

Complete line with short flow process and intelligent control for energy-saving, environmentally friendly, lightweight and high quality material.

PP, PLA supercritical CO2 foaming line

Integrated molding extrusion line for dry-free PET reaction and foaming

LFT impregnation and extrusion line

TSR reaction twin screw extruder line

TSD devolatilization twin screw extruder line

Rubber continuous dewatering line

Fluorine plastic modification granulating line

Granulating line for engineering plastic compounding and modification with low VOC

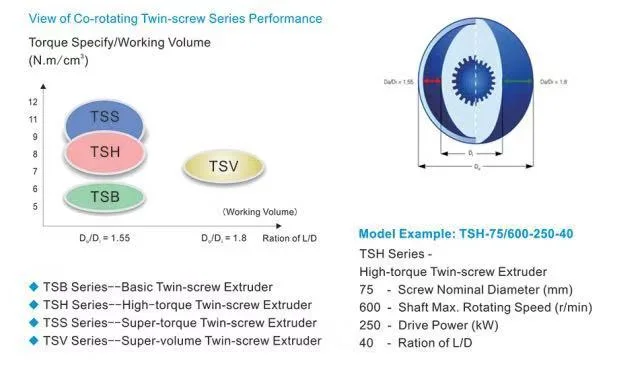

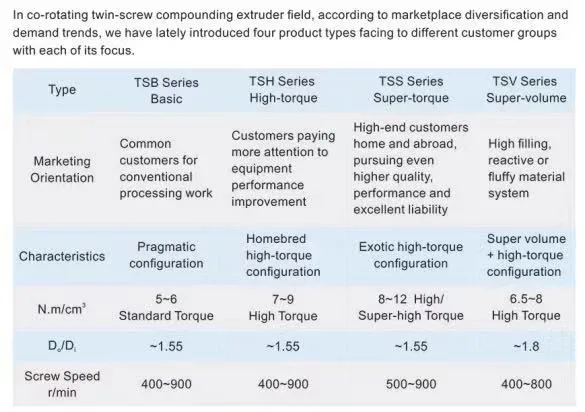

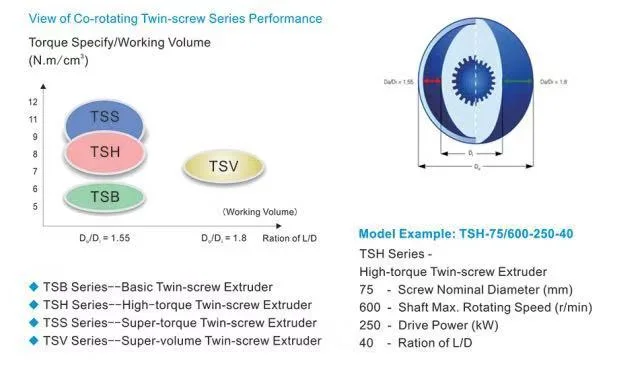

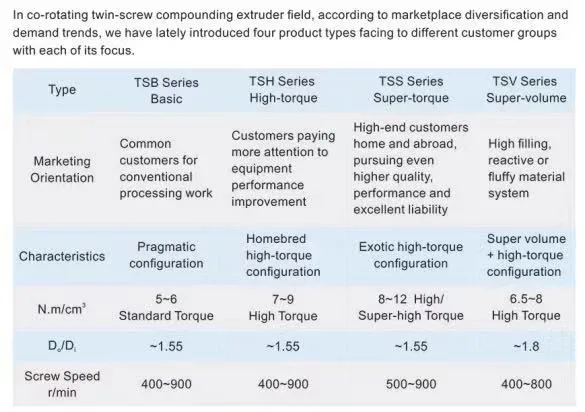

Twin screw extruder series:

TSB Seires - Basic twin screw extruder

TSH Series - High torque twin screw extruder

TSS Series - Super torque twin screw extruder

TSV Series - Super volume twin screw extruder

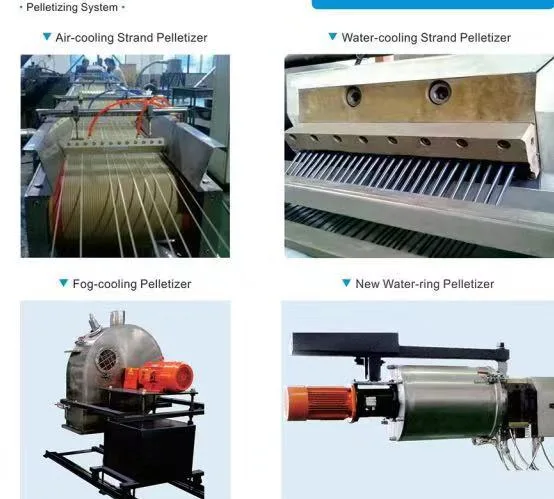

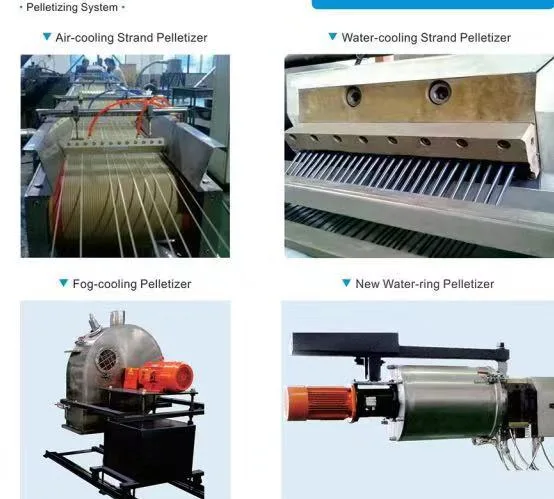

Cutting system :

Air cooling strand pelletizer

water cooling strand pelletizer

Fog cooling pelletizer

Water-ring cutting pelletizer

Under water cutting pelletizer

Air cooling hot face cutting pelletizer

CHUANGBO STAFF

in whole line applied for high polymer compounding and modication (including reactive extrusion and post -processing), and researching as well as developing applications in the sectors of related proces- sing technologies and engineering until turn-key project.

CHUANGBO WORKSHOP

CHUANGBO EXHIBITION

CHUANGBO PATENT

CHUANGBO MACHINE

Complete line with short flow process and intelligent control for energy-saving, environmentally friendly, lightweight and high quality material.

PP, PLA supercritical CO2 foaming line

Integrated molding extrusion line for dry-free PET reaction and foaming

LFT impregnation and extrusion line

TSR reaction twin screw extruder line

TSD devolatilization twin screw extruder line

Rubber continuous dewatering line

Fluorine plastic modification granulating line

Granulating line for engineering plastic compounding and modification with low VOC

Twin screw extruder series:

TSB Seires - Basic twin screw extruder

TSH Series - High torque twin screw extruder

TSS Series - Super torque twin screw extruder

TSV Series - Super volume twin screw extruder

Cutting system :

Air cooling strand pelletizer

water cooling strand pelletizer

Fog cooling pelletizer

Water-ring cutting pelletizer

Under water cutting pelletizer

Air cooling hot face cutting pelletizer

CHUANGBO STAFF

Type | Diameter (mm) | L/D | Screw speed (r/min) | Power (kw) | Torque grade (N.m) | Specific Torque (T/A3) | Capacity (kg/h) |

| TSB-18 | 18 | 32~60 | 600 | 2.2 | 17 | 5.0 | 0.5~10 |

| TSB-25 | 26 | 32~60 | 500 | 5.5 | 50.4 | 4.7 | 3~15 |

| 600 | 7.5 | 57.3 | 5.4 | 3~25 | |||

| TSB-35 | 35.6 | 32~68 | 500 | 15 | 138 | 5.1 | 10~55 |

| 600 | 18.5 | 141 | 5.2 | 10~90 | |||

| TSB-40 | 41 | 32~68 | 600 | 30 | 229 | 5.6 | 90~150 |

| TSB-52 | 51.4 | 32~68 | 500 | 45 | 413 | 5.2 | 135~225 |

| 600 | 55 | 420 | 5.3 | 165~275 | |||

| TSB-65 | 62.4 | 32~68 | 500 | 90 | 825 | 5.9 | 270~450 |

| 600 | 110 | 840 | 6.0 | 330~550 | |||

| TSB-75 | 71 | 32~68 | 500 | 132 | 1210 | 5.6 | 400~660 |

| 600 | 260 | 1222 | 5.7 | 480~800 | |||

| TSB-85 | 81 | 32~68 | 500 | 200 | 1834 | 5.9 | 600~1000 |

| TSB-95 | 93 | 32~68 | 500 | 280 | 2567 | 5.4 | 840~1400 |

| TSB-115 | 115.5 | 32~68 | 500 | 500 | 4584 | 5.2 | 1500~2500 |

| TSB-135 | 133 | 32~68 | 400 | 650 | 7449 | 5.6 | 1950~3250 |